T-Arm Rebuilding

What is in a Van Steel t-arm rebuild? First off, all our assemblies whether new or used are built the same. It’s all starts with properly prepared parts. Our used assemblies are completely torn down to bare metal. All races, seals, bushings, and paint is removed. We fully inspect these parts in their raw form for accuracy.

Bearing assemblies are checked for cracks, weld repairs, straightness, and for spun races. Spindles are checked for their bearing surface diameter for the inner and outer bearings. The threads are checked for mushrooming and if they are stripping out. Finally the spindles are checked for a run out on the face of spindle for less than .005. This ensures proper pad contact on the rear brakes due to the Corvette’s fixed caliper setup.

The Trailing arms are also completely stripped down to inspect for cracked welds and internal rusting. They are also jigged to insure they are straight and are visually inspected that they are not twisted. These last two measure are for extended bushing life and for proper alignment.

Finally, the caliper mounting bracket is inspected that it is free of cracks, is not bent (typically from the car bottoming out), and that the threads are clean and straight.

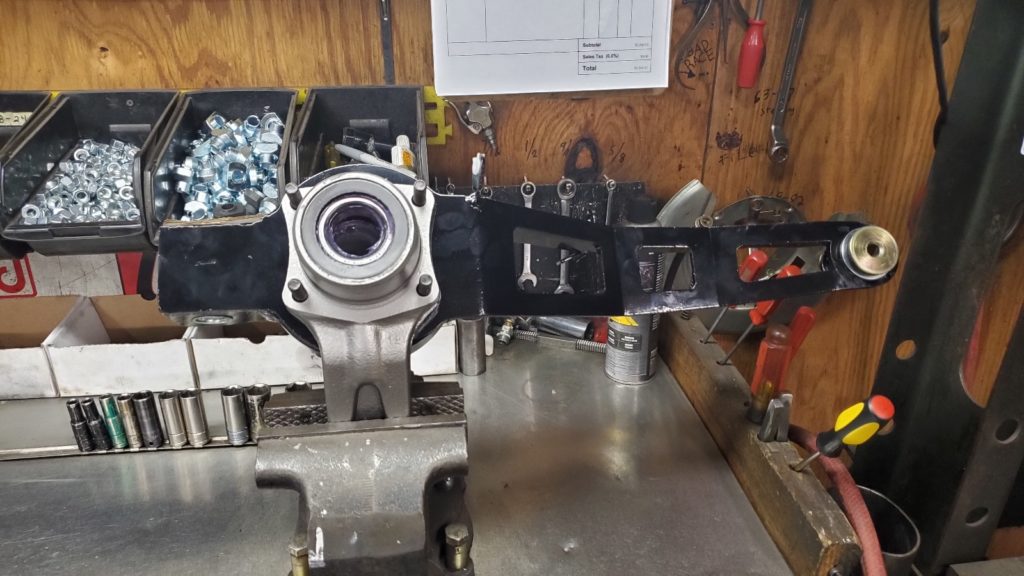

If any parts fail QC, we revise your quote with the new parts for you to review and approve. The parts then go to paint and powder coating. The bearing support, caliper mounting bracket and spindle are all primed and painted with epoxy paint. The trailing arm is powder coated gloss black.

All the freshly painted piece then go into assembly. We only use the highest quality parts available. These consist of Timken bearings and races plus SKF seals. The bearing support is then loaded and built to Van Steel spec, much tighter than GM specs. This is the heart of the Van Steel rebuild and our lifetime guarantee for your bearing assembly.

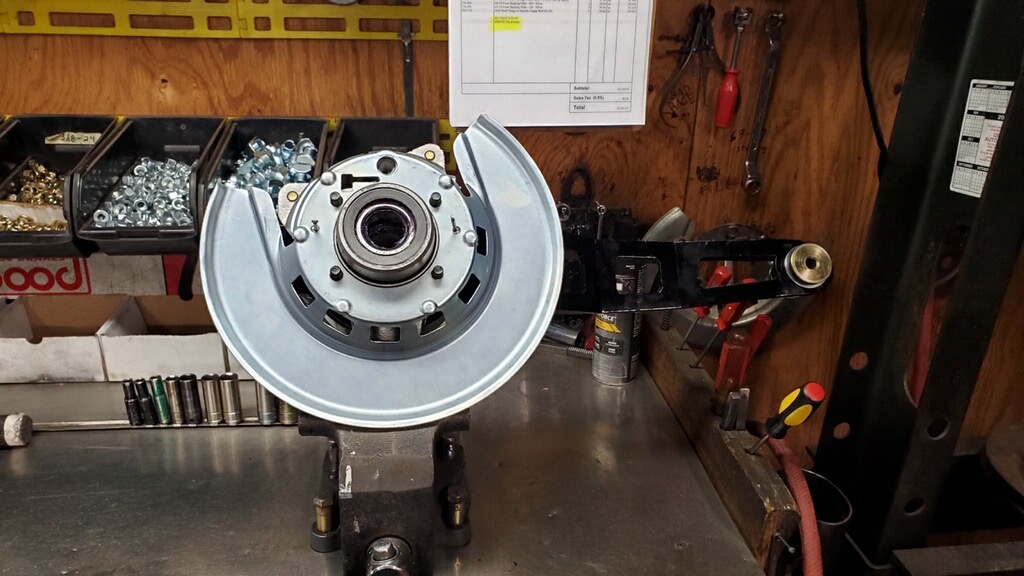

From here we mount the bearing support to the trailing arm, install the caliper mounting bracket, install the parking brake shoe retaining pins in the backing plate and install the backing plate. The parking brake retaining block and bolt are installed along with the shoes and hardware. We then bolt down the trailing arm to secure the assembly. The spindle is pressed in next to nearly complete the process.

The final step is also very critical. We mount the rotor and preform a final rotor run out. The parking brake adjust holes on the rotor and spindle are aligned to make your parking brake adjustments easier once you receive the trailing arms. If the rotor run out is under .005, we mark the spindle and rotor so the rotor is always installed matching this mark if ever removed for maintenance.

If a spindle flange is included, it is also inspected for excessive wear and that the bolt hole are straight and clean. The flange is then torqued down to a minimum of 100 ft lbs. If the cotter pin holes don’t line up, it’s torqued down further until they do.